China factory Low-Noise High-Performance Blue S Series Worm Gear Reducer Gearbox with CHINAMFG Output-Shaft air compressor oil

The China factory Low-Noise High-Performance Blue S Series Worm Gear Reducer Gearbox with CHINAMFG Output-Shaft air compressor oil is a top-quality product designed for various industrial applications. With its exceptional performance and low-noise operation, this gearbox is the perfect choice for your machinery needs.

Product Description

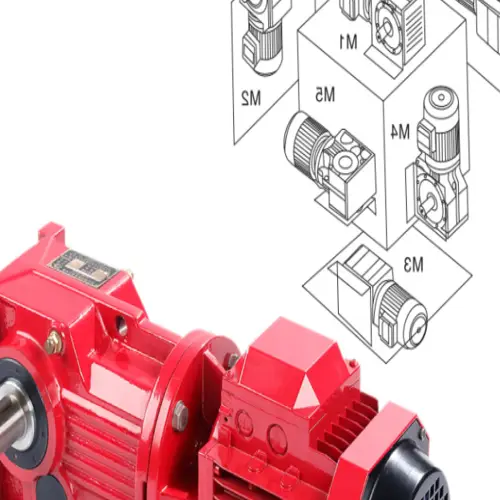

The SLS Helical-worm Gearbox is a high-quality product that offers superior performance. It comes in a customized color and is available in various mounting positions, including flange, hollow shaft, and solid shaft. The gear material used is 20CrMnTi, which ensures durability and reliability. With an efficiency rating of 94%-98%, depending on the transmission stage, this gearbox offers excellent power transmission. The input and output shafts are made of 40Cr material and undergo carburizing and quenching heat treatment for enhanced strength. The gear surface is processed using high precision grinding, resulting in smooth operation and low noise. The gearbox provides a large speed ratio range, ensuring versatility in your applications. With its compact structure and large bearing capacity, it offers stable operation and low energy consumption.

Advantages

- The compact structure and superior performance of this gearbox make it an excellent choice for industrial applications.

- Combining worm and helical gear technologies, it offers enhanced functionality.

- The large speed ratio range allows for flexible use in a variety of applications.

- The gear surface is processed using high precision grinding, ensuring optimal performance.

- With stable operation and low noise, this gearbox provides a comfortable working environment.

- It has a large bearing capacity and low energy consumption, making it a cost-effective choice.

Company Profile:

Our company specializes in supplying various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, competitive prices, and excellent customer service. Customization based on drawings and samples is always welcome.

FAQ

Q1: Are you a trading company or manufacturer?

A1: We are a manufacturer with our own factory.

Q2: What is the delivery time for your products?

A2: The delivery time is generally between 7-30 days, depending on the quantity.

Q3: Do you ship products to other countries?

A3: Yes, we can ship our products to various countries.

Q4: What are your accepted payment terms?

A4: We accept payments via T/T, Paypal, and Western Union.

Q5: What is the warranty period for your products?

A5: Our products come with a 1-year warranty.

All the content of this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Worm Gearbox

Worm gearbox offers several performance characteristics that make it an ideal choice for various applications:

- High Efficiency: The worm gearbox provides high efficiency, ensuring maximum power transmission.

- Compact Design: Its compact design allows for easy installation and integration into different systems.

- High Torque: The worm gearbox offers high torque output, making it suitable for heavy-duty applications.

- Smooth Operation: It provides smooth and quiet operation, minimizing noise and vibration.

- Reliable and Durable: Worm gearbox is known for its reliability and durability, ensuring long-lasting performance.

- Self-Locking: The self-locking feature of the worm gearbox prevents it from back-driving, providing enhanced safety and stability.

Types and Characteristics of Worm Gearbox

Worm gearboxes are available in various types, each offering unique characteristics:

- Non-Reversible Worm Gearbox: This type of worm gearbox is designed for one-directional power transmission, suitable for applications where back-driving is not required.

- Reversible Worm Gearbox: Reversible worm gearbox allows for bidirectional power transmission, making it suitable for applications that require back-driving.

- Right-Angle Worm Gearbox: The right-angle worm gearbox is designed to transmit power at a 90-degree angle, allowing for compact and space-saving installations.

Advantages of Worm Gearbox Made of Different Materials

Worm gearboxes can be made of various materials, each offering its own advantages:

- Cast Iron Worm Gearbox: Cast iron worm gearbox provides excellent strength and durability, making it suitable for heavy-duty applications.

- Aluminum Worm Gearbox: Aluminum worm gearbox is lightweight and corrosion-resistant, ideal for applications where weight and environmental factors are a concern.

- Stainless Steel Worm Gearbox: Stainless steel worm gearbox offers superior resistance to corrosion and high temperatures, making it suitable for demanding environments.

Application of Worm Gearbox in Various Fields

Worm gearbox finds its value and importance in various fields, including:

- Material Handling: Worm gearbox is widely used in material handling equipment, providing efficient power transmission for conveyor systems and lifting mechanisms.

- Packaging Machinery: Worm gearbox plays a crucial role in packaging machinery, ensuring precise and reliable movement of packaging components.

- Food Processing: The hygienic design and smooth operation of worm gearbox make it suitable for food processing equipment where cleanliness and efficiency are essential.

- Textile Industry: Worm gearbox is utilized in textile machinery for precise control and synchronized movement of various components.

Future Development Trends and Opportunities of Worm Gearbox Products

The future of worm gearbox products holds several development trends and opportunities:

- Advanced Materials: The use of advanced materials in worm gearbox construction will enhance performance and durability.

- Improved Efficiency: Continuous advancements in gear technology will lead to enhanced efficiency and power transmission capabilities.

- Smart and Connected Gearboxes: Integration of smart and connected technologies will enable remote monitoring and predictive maintenance of worm gearboxes.

- Automation and Industry 4.0: The increasing adoption of automation and Industry 4.0 principles will drive the demand for efficient and reliable worm gearbox solutions.

Choosing a Suitable Worm Gearbox

When selecting a suitable worm gearbox, several aspects should be considered:

- Load Requirements: Determine the torque and power requirements of your application to ensure the selected worm gearbox can handle the load.

- Ratio Selection: Choose the appropriate gear ratio to achieve the desired speed and torque output.

- Type of Gearbox: Consider the specific type of worm gearbox that best suits your application’s needs, such as non-reversible, reversible, or right-angle.

- Environmental Factors: Evaluate the environmental conditions, including temperature, humidity, and the presence of corrosive substances, to select a gearbox with suitable material and protection features.

- Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the worm gearbox to ensure it meets your long-term operational needs.

In conclusion, worm gearbox offers excellent performance characteristics, various types, and advantages based on different materials. Its application in different industries demonstrates its value and importance. The future holds promising trends and opportunities for worm gearbox products, driven by advancements in materials, efficiency, smart technologies, and automation. When choosing a suitable worm gearbox, considering load requirements, ratio selection, gearbox type, environmental factors, maintenance, and durability is crucial for optimal performance.

Author: Dream